Dongguan Samson Optoelectronics Technology Co., Ltd. specializes in vision inspection, laser measurement, spectral application, 3D reverse engineering, automation system integration technology and other total solutions. Samson inspection equipment systems have been widely used in: mobile phone industry, electronic connector industry, touch screen LCD panels, automotive parts processing parts, plastic moulds, electronic production, medical equipment, watch processing and other fields. The company takes innovation as the important driving force and core competitiveness of enterprise development, constantly introduces outstanding talents in the industry, and establishes a core management team with excellent technology, rich experience and sincere solidarity. After years of rapid development, the company has a stable customer base in the domestic market, established an excellent brand image, and developed into an advantageous enterprise in the segment of quality automation inspection.

MONOVIEW Measurement and Control:Providing the best solution for 3C electronic automation measurement and control_wap.hjhb861.com

January 1, 2019 MONOVIEW, the measurement and control system business unit established by Samson Optoelectronics Technology Co., Ltd, is a measurement and control system business unit derived and incubated in the company's upgrading and transformation, and is an important part of the company's efforts to further enhance its brand influence and market competitiveness. MONOVIEW measurement and control systems division inherits Samson Technology's fruitful scientific research achievements in the field of industrial automation and the core technologies of vision, laser and confocal spectroscopy, focusing on providing the best measurement and control solutions for the field of intelligent measurement and control.

In recent years, the renewal cycle of 3C electronic products has become faster and faster, and highly customized 3C equipment has shown stronger and stronger consumer attributes, the introduction of new 3C materials and 5G technology has revolutionized the processing technology of the 3C industry, and the demand for automated inspection systems has been increasing. equipment is an inevitable trend for the 3C electronics industry. Machine vision is the use of machines to replace the human eye to make measurements and judgments, to replace the human eye and human brain of quality inspectors with machine vision equipment for quality inspection of appearance.

For the time being, quality control is mainly done manually and will have the following 4 problems.

1. human subjective variation

2. fatigue

3. slow manual inspection speed

4. inability to achieve rapid online inspection

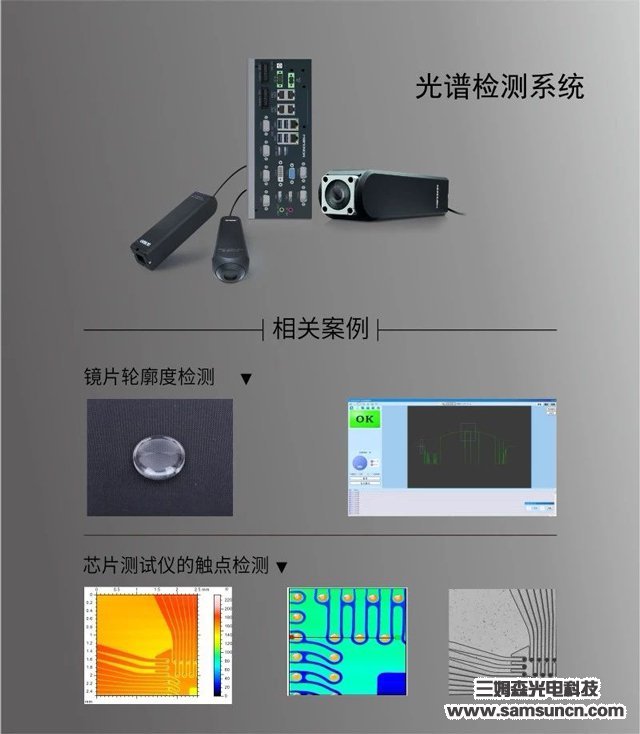

The current development direction of the Measurement and Control Systems Division is to make up for these four deficiencies by researching the use of core technologies such as vision, laser and confocal spectroscopy, focusing on comprehensive intelligent inspection in the field of back-end automation, making quality inspection standards more uniform, stable and fast, and at the same time, to solve the current situation of fragmented needs in various segments, combining deep learning algorithms to meet the customised needs of factories and proposing the best quality control solutions. The best measurement and control solutions.

Depending on the inspection requirements for different materials, MONOVIEW offers the best solutions based on vision, laser and spectral technology guidance and inspection components.

In the future, Makeway will continue to adhere to the business philosophy of "integrity, innovation, meticulousness and efficiency" and the corporate culture of "surpassing ourselves, pursuing excellence and common development", focusing on the field of light application and inspection in the midway assembly and testing process of the 3C electronics manufacturing industry. Through continuous technological innovation, we will enhance the market position of machine vision light application technology in the industry and provide customers with the best solution for high flexibility and high precision production assembly and quality inspection automation.

Returns List