With the continuous development of mobile technology, smart wearable devices have gradually become popular in people's lives, for the inspection of smart wearable products Samson has introduced a set of relatively complete inspection solutions, which can meet the height of metal or plastic structural parts of smart watches such as size, contour, gap segment difference, appearance defects and a variety of testing needs.

Measures almost all types of materials (metals, glass, ceramics, composites, semiconductors, etc.)

Inspection products: almost all types of materials can be measured (MIM parts, various small metal parts products, glass covers, ceramics, 3D composites, semiconductors, etc.)

Inspection products: almost all types of materials can be measured (MIM parts, various small metal parts products, glass covers, ceramics, 3D composites, semiconductors, etc.) Inspection function: flatness/height segment difference/transparent material

Inspection function: flatness/height segment difference/transparent material

Inspection accuracy: 0.005~0.01mm

Inspection accuracy: 0.005~0.01mm Inspection accuracy: 0.005~0.01mm

Inspection accuracy: 0.005~0.01mm

Productivity approx. 0.7S/point

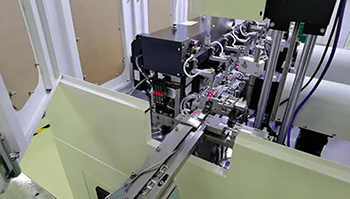

Productivity approx. 0.7S/point Inspection products: suitable for a variety of high-precision metal small parts; universal, when not moving the hardware can be universal inspection of a variety of similar products.

Inspection products: suitable for a variety of high-precision metal small parts; universal, when not moving the hardware can be universal inspection of a variety of similar products. Inspection function: product dimension, flatness, height/thickness dimension measurement

Inspection function: product dimension, flatness, height/thickness dimension measurement Inspection accuracy: up to ±0.005mm

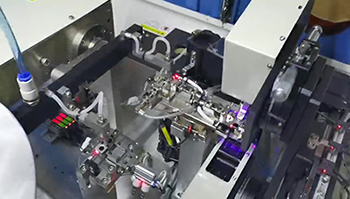

Inspection accuracy: up to ±0.005mm Main measurement method: CCD visual inspection + laser measurement

Main measurement method: CCD visual inspection + laser measurement Production capacity up to 3500 PCS/H

Production capacity up to 3500 PCS/H Inspection products: Suitable for mobile phone keys, camera rings, card holders, Type-C connectors, paper clips, connectors and other metal precision machined parts, medical equipment small parts, plastic small parts, etc.

Inspection products: Suitable for mobile phone keys, camera rings, card holders, Type-C connectors, paper clips, connectors and other metal precision machined parts, medical equipment small parts, plastic small parts, etc. Inspection function: Product profile size, flatness, position, height difference, appearance defects, etc.

Inspection function: Product profile size, flatness, position, height difference, appearance defects, etc. Inspection accuracy: up to ±0.005mm

Inspection accuracy: up to ±0.005mm Main measurement method: CCD visual inspection + laser measurement

Main measurement method: CCD visual inspection + laser measurement Production capacity up to 3600PCS/H

Production capacity up to 3600PCS/H Inspection products: Suitable for 3D composite materials, glass covers, various metal products

Inspection products: Suitable for 3D composite materials, glass covers, various metal products Inspection function: measurement of distance, radius, angle, curvature and other dimensions

Inspection function: measurement of distance, radius, angle, curvature and other dimensions Inspection accuracy up to ±0.005mm

Inspection accuracy up to ±0.005mm Main measurement method: CCD visual inspection

Main measurement method: CCD visual inspection Inspection features: universal equipment, accurate flash measurement, measurement results do not vary from person to person

Inspection features: universal equipment, accurate flash measurement, measurement results do not vary from person to person Products tested: 3D composite materials, mobile phone back covers, glass back covers, mobile phone mid-frames, camera mounts, watch structural parts, rechargeables, 5G ceramics, etc.

Products tested: 3D composite materials, mobile phone back covers, glass back covers, mobile phone mid-frames, camera mounts, watch structural parts, rechargeables, 5G ceramics, etc. Inspection functions: external dimensions, height dimensions, flatness, perpendicularity inspection

Inspection functions: external dimensions, height dimensions, flatness, perpendicularity inspection Inspection accuracy up to ±0.005mm

Inspection accuracy up to ±0.005mm Main measurement method: CCD visual inspection + laser measurement

Main measurement method: CCD visual inspection + laser measurement Production capacity up to 550PCS/H

Production capacity up to 550PCS/HReal-time image acquisition, production data screen display query output, printout, can be docked to the production management software

Repeatability can be measured and evaluated periodically by yourself and records can be kept, and inspection accuracy can be effectively maintained.

Production report output, data storage for defective product analysis, process improvement

Automated, efficient and accurate, low misjudgment, multi-measurement integration, easy to operate, digital

Learn about the application ofSmartwatch metal and plastic structural parts inspectionin production with a one-minute video

Please fill in your personal information, we will get in touch with you as soon as possible